“For the past few years, I’ve worked closely with Solaxis Ingenious Manufacturing on many di˛erent types of jobs and applications and find them to be a valuable resource in my everyday activities. They understand and respect the requirements I give to them and always have the best interests of my projects in mind. They are e°cient in every way and in the fast-paced world of 3D printing with which I deal on a daily basis, I can always depend on them to come through for me and deliver a quality product…on time!!”

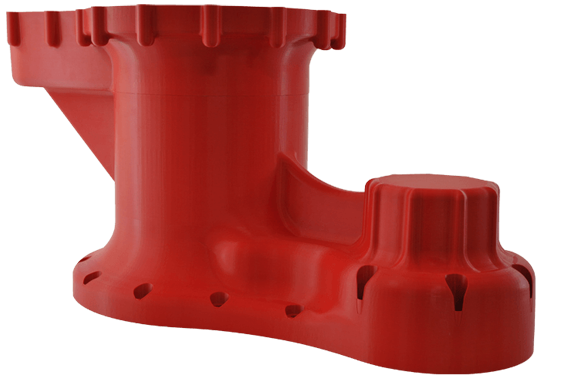

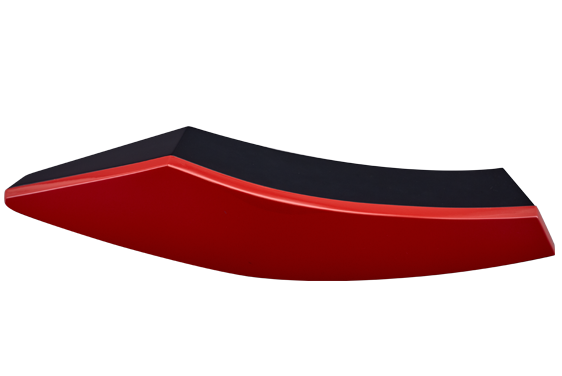

BRP | Bombardier Recreative Products

Technical Services