Given high startup costs and the difficulty of creating geometrically complex or personalized parts, traditional manufacturing processes such as injection molding or forming are poorly adapted to low-volume production. Because it solves all of these problems, additive manufacturing (3D printing) is a highly competitive solution.

Leveraging 3D printing techniques enables us to produce high-quality parts in limited quantities, resulting in competitive unit costs and production timeframes. The technology also offers you the possibility of testing several different models in the same production batch.

Moreover, using 3D printing in the aeronautics industry makes for lower fuel consumption thanks to lighter parts.

Enjoy advantageous production capacities:

Your commitment remains minimal, given that the project will not require you to order major volumes. Our unfailing dedication to respecting delivery deadlines and fast manufacturing timelines prevent you from paying fees incurred by lateness.

Trust a team that stands by its commitments:

Our 3D printing technology provides greater design freedom:

Enjoy a quality final product:

Industrial

After having developed an ingenious system to prevent ice from forming on antennae, the customer needed only a few parts to be able to break the ice.

Industrial

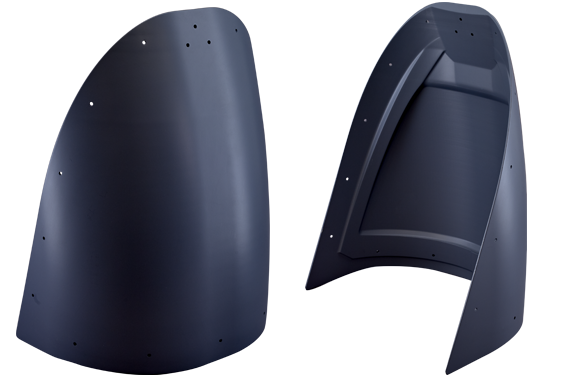

To build a large-format amplifier part with an unusual curved shape and high standards

To achieve a superior sound quality together with an aesthetically pleasing look, Askja’s designers realized the complex design of the large format amplifier incorporated an unusual curved shape that made it nearly impossible to manufacture traditionally.

The design freedom of 3D printing allows them to produce any shape they came up with, with no geometric limitations. This capability proved to be the cornerstone to realizing the design and production of our hybrid amplifier, filters, and power supply unit.